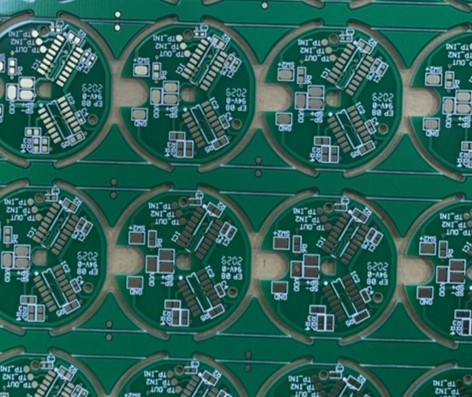

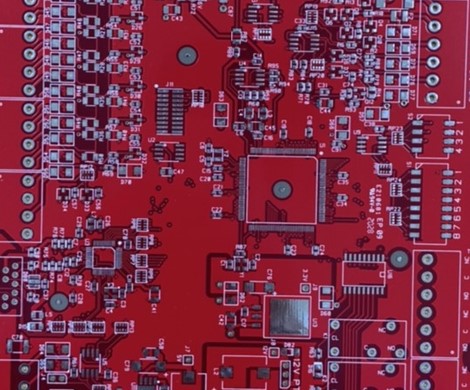

Surface Finish Is the Connection between Copper PAD and SMT Solder

Similar to solder mask, however, surface finish does not protect copper trace but the exposed copper PAD after solder mask process. As the connection between copper PAD and SMT solder, a few common options and comparison are as below.

OSP (Organic Solder-ability Preservative)

Advantage: low cost / good flatness / good solder-ability

Disadvantage: short storage time / not good for second time reflow

Lead Free HASL (Hot Air Solder Level)

Advantage: better cost / good solder-ability / better storage time

Disadvantage: bad flatness / not good for small component

ENIG (Electro-less Nickel Immersion Gold)

Advantage: long storage time / good flatness / good for second time reflow

Disadvantage: high cost / less welding strength

OSP (Organic Solder-ability Preservative)

Advantage: low cost / good flatness / good solder-ability

Disadvantage: short storage time / not good for second time reflow

Lead Free HASL (Hot Air Solder Level)

Advantage: better cost / good solder-ability / better storage time

Disadvantage: bad flatness / not good for small component

ENIG (Electro-less Nickel Immersion Gold)

Advantage: long storage time / good flatness / good for second time reflow

Disadvantage: high cost / less welding strength