- Home

- Equipments

PCB Manufacturing Equipment

As our customer requirements are constantly changing and increasing ExPlus is committed to a continuous improvement in manufacturing process, machinery and technologies available. ExPlus has production lines of Flex and rigid Flex in China and PCB and assembling lines in both Taiwan and China simultaneously. To stay more competitive ExPlus is your 1 stop solution in PCB Fabrication, component procurement, assembly and turnkey jobs or choose any one of the options that suits your demands.

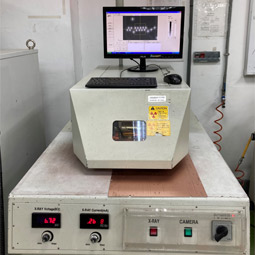

X-Ray Fluorescence Measuring

Measure the thickness of the extremely thin coating on the PCB surface and analyze the composition of related materials with the non-destructive and non-contact method to ensure product quality and quality control

Microscope

Microscope to check inner layer from microsection part per production batch

Two-dimensional Measurement

Two-dimensional measurement to measure PCB size and every needed location

TDR Impedance Measurement

TDR Impedance Measurement to measure the impedance

CCD Microscope

Used to assist appearance inspection and confirm relevant specifications at the same time. Increase the accuracy of abnormal defect judgment and improve quality control capabilities.

Reflow

It is used to simulate customer reflow furnace setting parameters and optimize solderability, improve soldering ability, and verify related reliability.

V-Cut Residual Thickness Measurement

Measure the residual thickness of the V-cut groove on the PCB to facilitate the panalization process.

X-Ray Inspection

Using the X-ray penetration principle, inspect the PCB inner layer circuit and the drilling offset situation. Suitable for checking the alignment of the inner layer after pressing and drilling.

Automatic Visual Inspection (AVI)

The Automatic Visual Inspection machine is a visual inspection using computer vision.

AVI machines can not only maintain the high quality of production, but also aid in standardizing inspection. There is a minimum size of the defect that is capable of being defected by the machine, which is 54 um.

AVI machines can not only maintain the high quality of production, but also aid in standardizing inspection. There is a minimum size of the defect that is capable of being defected by the machine, which is 54 um.

Programmable Temperature & Humidity Chamber

Inspect the product's adaptability and characteristics under different environmental conditions.

With this equipment, we can check product durability by raising the temperature and accelerating circuit board aging.

With this equipment, we can check product durability by raising the temperature and accelerating circuit board aging.