CNC makes the PCB as the shape on hand

CNC makes the PCB as the shape on hand

Do you know that the PCB you receive from your supplier is not the size on those production equipment and go through all the processes?

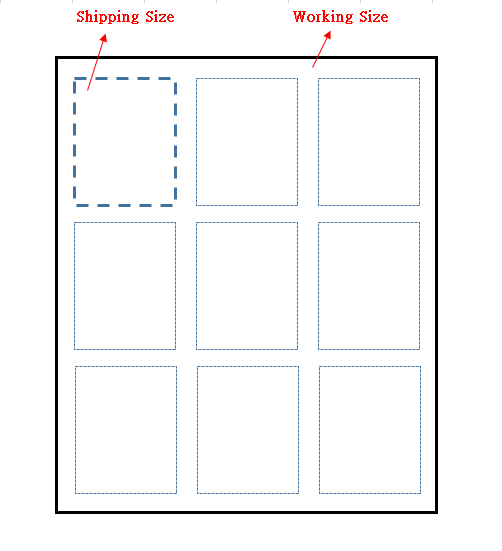

What we produce on equipment is the “working size” and after CNC the PCB becomes the “shipping size” of your design.

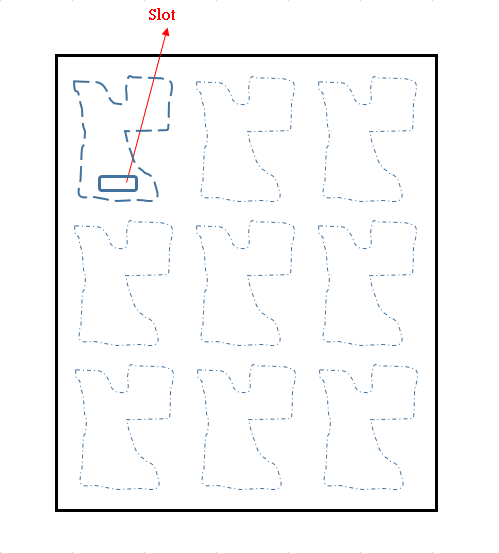

Except to separate shipping size from working size, CNC is also used for shaping your PCB outline, the slot design in board, or bigger drilling hole that is oversized.

Do you know that the PCB you receive from your supplier is not the size on those production equipment and go through all the processes?

What we produce on equipment is the “working size” and after CNC the PCB becomes the “shipping size” of your design.

Except to separate shipping size from working size, CNC is also used for shaping your PCB outline, the slot design in board, or bigger drilling hole that is oversized.

Maybe you would like to read more:

- What is the role of holes on printed circuit boards (PCB)? What are PTH / NPTH holes? And what’s the difference between two of them?

- What does the term “X-out” mean in the PCB industry?

- What in the world are the major causes of this PCB bending issue?

- Panel Copper Plating → PTH (Plated Through Hole)